Printing & Packaging Industry Solutions by Precite.ai

With over 40 years of experience in serving the printing and packaging sector, Precite.ai has developed custom-made HVAC and automation solutions specifically tailored to the unique demands of this industry. Our systems ensure optimal print quality, consistent production, and energy-efficient operations.

Our Solution

Industrial Chillers

Our industry-specific chillers are designed to maintain precise temperatures for presses, UV curing units, and dampening systems. They ensure consistent ink viscosity, reduce downtime, and increase equipment lifespan.

Humidification System

Maintaining proper humidity (45–60 % RH) in printing is crucial to prevent paper from drying, shrinking, or curling, which causes misfeeds, poor registration, and print defects. Low humidity (below 40 %) increases static electricity, attracting dust, disrupting sheet handling, and damaging sensitive equipment. Controlled humidity ensures consistent paper dimensions, better ink adhesion, reduced downtime, and overall print quality stability, making it essential for efficient and high-quality printing operations.

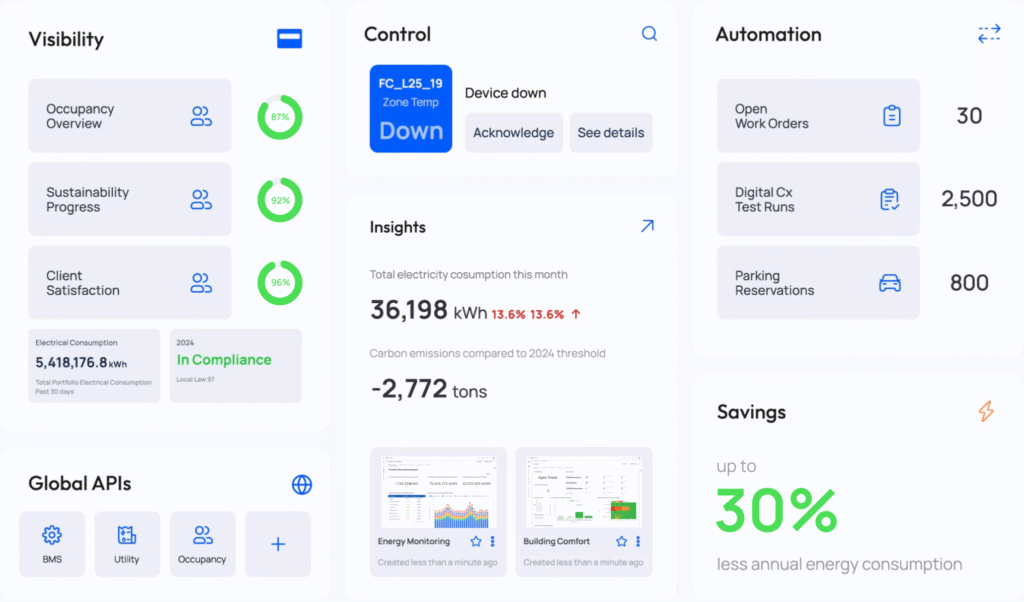

Building Management System & Factory Automation

With AI-powered automation and real-time monitoring, operators can track temperature, humidity, and chiller performance across multiple zones. Our systems provide predictive maintenance alerts, remote access, and data-driven insights, allowing faster decision-making and uninterrupted production

Technotrans Machine Maintenance & AMC

We are experts in Technotrans chillers integrated in Heidelberg and Roland presses. Our team provides preventive maintenance, AMC services, and rapid troubleshooting, ensuring your machines run at peak performance without production losses

Industrial Chillers

Our industry-specific chillers are designed to maintain precise temperatures for presses, UV curing units, and dampening systems. They ensure consistent ink viscosity, reduce downtime, and increase equipment lifespan.

Humidification System

Maintaining proper humidity (45–60 % RH) in printing is crucial to prevent paper from drying, shrinking, or curling, which causes misfeeds, poor registration, and print defects. Low humidity (below 40 %) increases static electricity, attracting dust, disrupting sheet handling, and damaging sensitive equipment. Controlled humidity ensures consistent paper dimensions, better ink adhesion, reduced downtime, and overall print quality stability, making it essential for efficient and high-quality printing operations.

Building Management System & Factory Automation

With AI-powered automation and real-time monitoring, operators can track temperature, humidity, and chiller performance across multiple zones. Our systems provide predictive maintenance alerts, remote access, and data-driven insights, allowing faster decision-making and uninterrupted production

Technotrans Machine Maintenance & AMC

We are experts in Technotrans chillers integrated in Heidelberg and Roland presses. Our team provides preventive maintenance, AMC services, and rapid troubleshooting, ensuring your machines run at peak performance without production losses

Industrial Chillers

Our industry-specific chillers are designed to maintain precise temperatures for presses, UV curing units, and dampening systems. They ensure consistent ink viscosity, reduce downtime, and increase equipment lifespan.

Humidification System

Maintaining proper humidity (45–60 % RH) in printing is crucial to prevent paper from drying, shrinking, or curling, which causes misfeeds, poor registration, and print defects. Low humidity (below 40 %) increases static electricity, attracting dust, disrupting sheet handling, and damaging sensitive equipment. Controlled humidity ensures consistent paper dimensions, better ink adhesion, reduced downtime, and overall print quality stability, making it essential for efficient and high-quality printing operations.

Building Management System & Factory Automation

With AI-powered automation and real-time monitoring, operators can track temperature, humidity, and chiller performance across multiple zones. Our systems provide predictive maintenance alerts, remote access, and data-driven insights, allowing faster decision-making and uninterrupted production

Technotrans Machine Maintenance & AMC

We are experts in Technotrans chillers integrated in Heidelberg and Roland presses. Our team provides preventive maintenance, AMC services, and rapid troubleshooting, ensuring your machines run at peak performance without production losses

Technotrans Machine Maintenance & AMC

We are experts in Technotrans chillers integrated in Heidelberg and Roland presses. Our team provides preventive maintenance, AMC services, and rapid troubleshooting, ensuring your machines run at peak performance without production losses

Want a Custom Quotation or Consultancy ?

Write to us at : info@precite.ai or whatsapp/call us at +91 9625777543

Want a Custom Quotation or Consultancy ?

Write to us at : info@precite.ai or whatsapp/call us at +91 9625777543

Sign up for our newsletter

News, insights and resources from the world of smart building management.

Solutions

Copyright © 2025 PRECITE.AI. All rights reserved.

Industries

Company

Menthol, Aroma, & Allied

Chemicals

Pharma & Chemicals

Test Chamber & Process System