Indoor Saffron Farming Explained: Technology, Process, and Commercial Potential

- Archit Dosajh

- Jan 2

- 4 min read

Introduction: Why Traditional Saffron Farming Is No Longer Enough

Saffron is one of the most valuable agricultural products in the world, but it is also one of the most fragile to cultivate. Traditional open-field saffron farming depends heavily on climate stability, seasonal precision, and skilled manual intervention. Even minor fluctuations in temperature, humidity, or soil moisture can drastically impact yield quality and consistency.

For agribusiness investors, food processors, and industrial buyers, this variability creates operational risk and limits scalability.

Indoor saffron farming—powered by controlled environments, industrial HVAC systems, sensors, and AI-driven automation—solves these challenges by converting saffron cultivation into a predictable, repeatable, and commercially scalable process.

What Is Indoor Saffron Farming?

Indoor saffron farming is a form of controlled environment agriculture (CEA) where saffron corms are cultivated inside insulated chambers rather than open fields. These chambers replicate optimal natural conditions using engineered systems.

Unlike conventional farming, indoor saffron production is:

Climate-independent

Location-agnostic

Year-round feasible

Data-driven and automatable

The result is consistent stigma quality, reduced crop loss, and measurable production efficiency.

The Technology Stack Behind Indoor Saffron Cultivation

Successful indoor saffron farming relies on the convergence of multiple industrial technologies rather than agricultural guesswork.

1. Controlled Climate Chambers

Insulated cold-room-style chambers maintain precise environmental conditions required at each growth stage.

Key parameters include:

Temperature stability (critical during flowering)

Relative humidity control

Fresh air exchange

CO₂ balance

Proper Grow Light

These chambers are structurally similar to industrial cold storage rooms but optimized for crop physiology rather than storage alone.

2. Industrial HVAC and Chillers

Saffron flowering is highly sensitive to temperature deviation. Industrial-grade HVAC systems and chillers ensure:

Uniform airflow distribution

Rapid response to load changes

Stable temperature bands without thermal shock

This is where indoor saffron farming transitions from agriculture to industrial process control.

3. Sensors, PLCs, and Automation Controllers

Modern saffron chambers use:

Temperature and humidity sensors

Soil or substrate moisture sensors

PLC-based controllers

Automated fans, lighting, and humidifiers

Automation removes dependency on manual judgment and ensures repeatability across batches.

Step-by-Step Indoor Saffron Farming Process

Stage 1: Corm Selection and Preparation

High-quality saffron corms are graded by size and health. Indoor systems allow uniform treatment, reducing biological variance.

Stage 2: Controlled Dormancy Simulation

Temperature and humidity are adjusted to simulate natural dormancy cycles, triggering synchronized flowering later.

Stage 3: Flower Induction Phase

Precise thermal and humidity control initiates flowering. Even a 1–2°C deviation at this stage can affect stigma yield.

Stage 4: Harvest and Post-Harvest Handling

Indoor setups allow clean, contamination-free harvesting and immediate drying under controlled airflow conditions.

Commercial Advantages of Indoor Saffron Farming

Predictable Yield and Quality

Indoor systems eliminate weather risk, enabling consistent grading and pricing—critical for export-oriented businesses.

Reduced Crop Failure Risk

Automation and predictive alerts significantly reduce losses caused by human error or sudden environmental changes.

Scalability for Industrial Buyers

Indoor saffron production aligns with factory-style scaling—add chambers, replicate processes, expand output.

Energy Efficiency and Cost Optimization

While indoor farming is energy-intensive, intelligent system design offsets this through:

Variable frequency drives (VFDs)

AI-based load optimization

Predictive maintenance on chillers and HVAC

Heat recovery where applicable

Over time, optimized systems outperform traditional farming on cost per gram of usable saffron.

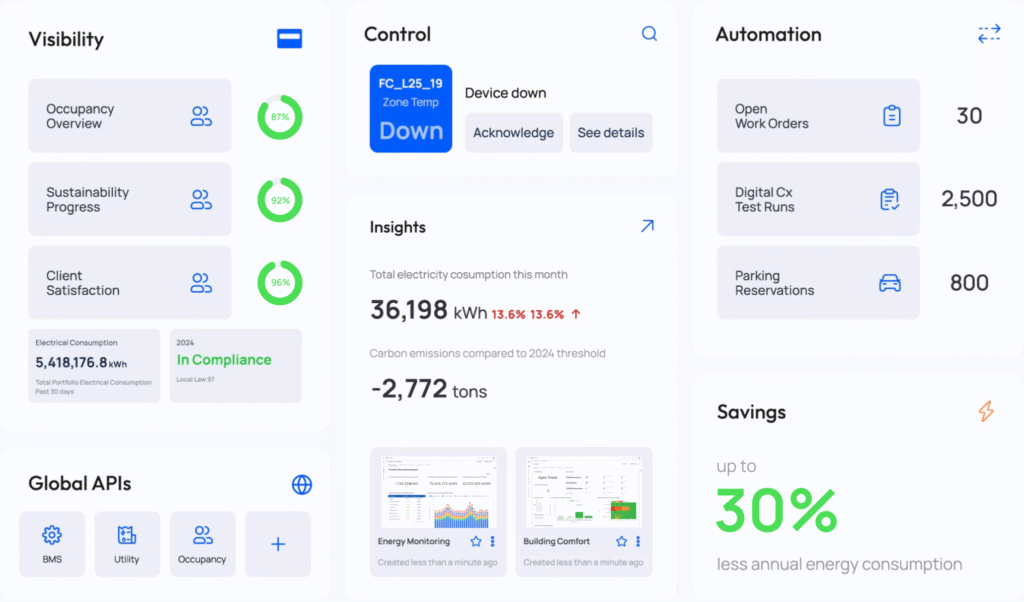

How Precite.ai Enables Scalable Indoor Saffron Farming

Precite.ai approaches indoor saffron farming as an industrial automation problem, not a hobby-scale agricultural experiment.

Integrated Solutions Include:

AI-controlled saffron cultivation chambers

Industrial chillers optimized for agricultural loads

Smart HVAC intelligence for precise climate zones

Predictive maintenance to prevent system failures

Centralized dashboards for real-time monitoring

By combining cold-room engineering expertise with AI-driven control logic, Precite.ai helps agribusinesses move from pilot setups to commercially viable production systems.

This same automation philosophy is already proven in manufacturing plants, cold storage facilities, and HVAC-intensive industries—making it reliable and scalable.

Industrial Use-Cases Beyond Agriculture

Indoor saffron farming shares infrastructure similarities with:

Pharmaceutical clean rooms

Food processing cold rooms

Mushroom cultivation chambers

Microgreen vertical farms

Organizations already operating HVAC-heavy environments can repurpose existing expertise to enter high-value crop production with minimal learning curve.

FAQs: Indoor Saffron Farming

Is indoor saffron farming commercially viable?

Yes. With proper automation and energy optimization, indoor saffron farming offers predictable yield and premium-quality output suitable for commercial markets.

What is the biggest risk in indoor saffron farming?

Environmental instability. This is why industrial-grade HVAC, sensors, and AI control are non-negotiable for success.

How much space is required?

Indoor saffron systems are modular. Production can scale from small chambers to industrial multi-room facilities.

Does indoor saffron farming require skilled farmers?

It requires system operators and process managers rather than traditional field labor, shifting skills toward automation and monitoring.

Can indoor saffron farming work in urban or industrial zones?

Yes. Controlled systems are location-independent and ideal for urban or industrial deployment.

Conclusion: Saffron Farming Is Becoming an Industrial Process

Indoor saffron farming represents a shift from climate-dependent agriculture to controlled, data-driven production. For investors, agribusiness leaders, and industrial buyers, this model offers reliability, scalability, and measurable ROI.

Organizations that treat saffron cultivation as an engineered system—supported by HVAC intelligence, AI monitoring, and automation—will define the future of high-value crop production.

Explore how Precite.ai’s industrial automation expertise can help you design, deploy, and scale indoor saffron farming systems built for commercial success.

Comments