Steam Distillation of Menthol: Process, Equipment, and Industrial Workflow

- Archit Dosajh

- Jan 3

- 4 min read

Introduction: Why Steam Distillation Still Dominates Menthol Production

Menthol is a high-value compound widely used in pharmaceuticals, FMCG products, cosmetics, food processing, and aromatics. Despite advancements in chemical synthesis, steam distillation of menthol-rich mint oils remains the most trusted industrial method due to its purity, scalability, and regulatory acceptance.

However, traditional distillation plants often struggle with inconsistent yields, high energy consumption, temperature instability, and unplanned downtime. This is where modern industrial automation, intelligent chillers, and AI-based process control transform a conventional menthol distillation setup into a predictable, efficient, and scalable operation.

This guide explains the complete industrial workflow of steam distillation of menthol, the equipment involved, and how automation-driven systems significantly improve operational ROI.

What Is Steam Distillation of Menthol?

Steam distillation is a separation process where steam passes through menthol-bearing plant material (typically Mentha arvensis or peppermint leaves) to volatilize essential oils. These vapors are then condensed, and menthol-rich oil is separated from water.

Why Steam Distillation Is Preferred

Preserves thermally sensitive menthol compounds

Produces high-purity essential oil

Scalable from small batch to continuous industrial plants

Accepted by pharmaceutical and food-grade standards

Industrial Steam Distillation Process: Step-by-Step

1. Raw Material Preparation

Harvested mint leaves are partially dried to optimize oil concentration

Moisture content is controlled to avoid steam channeling

Uniform particle size ensures consistent steam penetration

Industrial insight: Automated drying chambers with humidity control reduce raw material variability.

2. Steam Generation

Steam is generated using industrial boilers

Pressure and temperature must remain stable to prevent compound degradation

Key control parameters:

Steam pressure

Steam temperature

Flow rate

Poor steam control directly reduces menthol yield and increases fuel costs.

3. Distillation Vessel Operation

Steam passes through the biomass bed

Volatile menthol vapors are released

Residence time is critical

Automation challenge:Manual control often leads to overheating, uneven extraction, and batch inconsistency.

4. Condensation & Cooling

Vapors pass through shell-and-tube or plate condensers

Cooling water or industrial chillers condense vapor into liquid

Critical dependency:Cooling efficiency directly impacts oil recovery rate.

5. Oil–Water Separation

Condensed liquid enters a separator

Menthol oil (lighter) separates from hydrosol

Oil is further processed or crystallized if required

6. Menthol Crystallization (Optional)

Controlled cooling allows menthol crystals to form

Requires precise temperature gradients

This step is highly sensitive and benefits most from automation and AI-based control.

Key Equipment Used in Menthol Steam Distillation Plants

Equipment | Function | Automation Opportunity |

Steam Boiler | Steam generation | Pressure & efficiency optimization |

Distillation Vessel | Oil extraction | Temperature & residence-time control |

Condenser | Vapor condensation | Chiller load optimization |

Industrial Chiller | Cooling | Predictive maintenance |

Separator | Oil-water separation | Flow consistency monitoring |

Cold Room / Storage | Menthol storage | HVAC intelligence |

Operational Challenges in Traditional Distillation Plants

Energy losses due to inefficient steam control

Manual monitoring leading to batch variability

Condenser fouling causing yield drop

Chiller breakdowns halting production

No predictive insights into failures

For industrial-scale menthol production, these issues translate into lost batches, higher operational costs, and unstable quality.

Role of Automation and AI in Menthol Distillation

Smart Temperature & Steam Control

AI-based controllers dynamically adjust:

Steam pressure

Heat input

Distillation duration

This ensures optimal extraction without overheating.

Intelligent Chiller & Condenser Optimization

AI-driven chillers:

Match cooling load in real time

Reduce energy consumption

Prevent condenser inefficiency

This directly improves oil recovery and reduces electricity costs.

Predictive Maintenance for Critical Assets

Using sensor data, AI systems predict:

Boiler fouling

Pump failure

Chiller compressor stress

Downtime is prevented before it occurs.

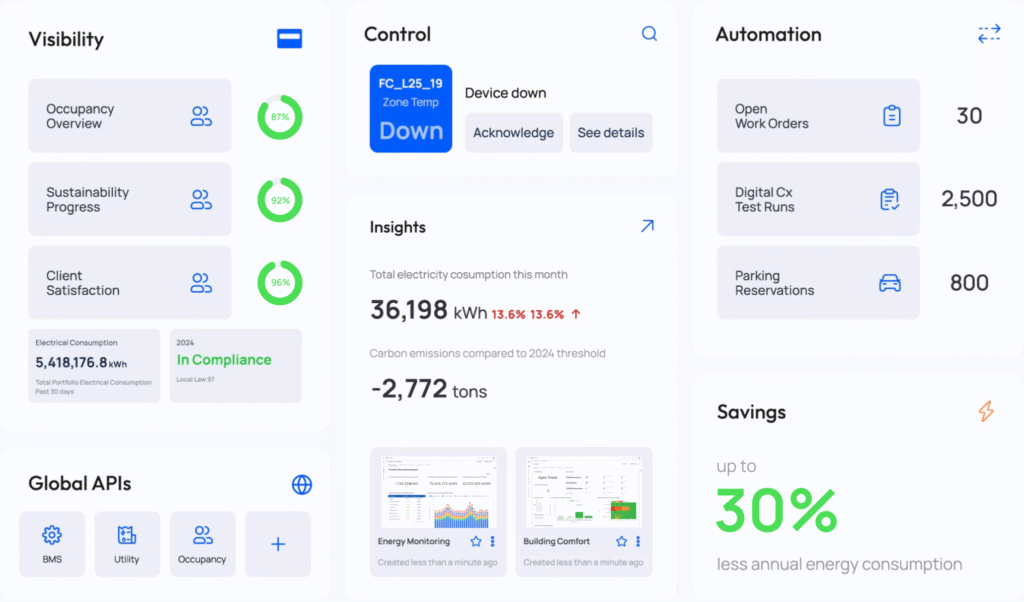

How Precite.ai Transforms Menthol Distillation Plants

Precite.ai specializes in AI-powered industrial automation systems for process industries. In menthol distillation plants, Precite.ai delivers:

End-to-End Intelligent Control

Real-time monitoring of steam, temperature, and pressure

Automated distillation cycle optimization

Centralized dashboards for plant managers

Energy-Efficient Cooling & HVAC Intelligence

AI-controlled industrial chillers

Smart condenser temperature management

Cold room automation for menthol storage

Predictive Maintenance & ROI Visibility

Equipment health scoring

Failure prediction alerts

Energy consumption analytics

Business outcome:

Higher menthol yield per batch

Lower energy cost per kg

Consistent pharmaceutical-grade quality

Industrial Use-Cases

Pharmaceutical Manufacturing

High-purity menthol for formulations

Strict temperature traceability

Automated compliance logs

FMCG & Personal Care

Large-volume distillation with batch consistency

Reduced wastage through AI optimization

Cold Storage & Export Units

Menthol crystal storage with humidity and temperature control

Reduced sublimation losses

FAQs: Steam Distillation of Menthol

What is the ideal temperature for menthol steam distillation?

Steam temperature typically ranges between 100–110°C, while precise control prevents degradation and improves yield.

Why is chilling important in menthol distillation?

Efficient condensation ensures maximum oil recovery. Poor cooling leads to vapor losses and reduced output.

Can menthol distillation be fully automated?

Yes. Modern plants use AI-driven PLC systems to automate steam flow, cooling, and batch timing.

How does automation improve menthol yield?

Automation maintains optimal extraction conditions throughout the cycle, reducing human error and variability.

Is steam distillation suitable for large-scale menthol production?

Yes. It is the most widely adopted industrial method due to scalability and regulatory acceptance.

Conclusion: Building a Future-Ready Menthol Distillation Plant

Steam distillation of menthol remains a proven industrial process, but its profitability now depends on intelligent control, energy optimization, and predictive maintenance.

By integrating AI-driven automation, smart chillers, and real-time analytics, manufacturers can achieve:

Consistent product quality

Lower operational costs

Higher equipment uptime

Scalable production

For decision-makers planning new distillation plants or upgrading existing ones, automation is no longer optional—it is a competitive necessity.

Explore related topics on Precite.ai:

AI in Industrial Chillers

Smart Cold Rooms for Process Industries

Predictive Maintenance in Manufacturing

HVAC Intelligence for Energy Optimization

Ready to modernize your menthol distillation process?Connect with Precite.ai to design an intelligent, efficient, and future-proof industrial system.

Comments